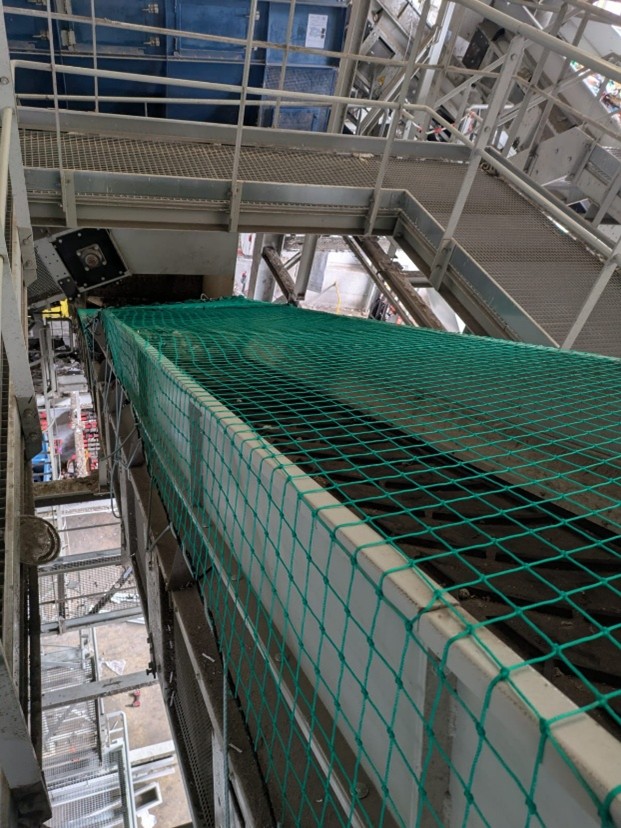

Securing a conveyor while maintaining visual control of the flow

Our client is one of France’s largest players in waste treatment and recovery, recognized for its operational excellence, high safety standards, and environmental commitment.

At one of its industrial sites, the conveyors used to transport solid waste were historically protected with traditional opaque tarps. Their purpose was to prevent any dispersion of dust or materials.

However, these tarps severely limited visibility on the conveyor belt. Following a DREAL inspection, the company had to comply with new fire-safety rules requiring the ability to immediately spot any anomaly, in particular an incipient fire.

Challenges encountered

Several major issues had to be taken into account:

- Fire safety: the opaque tarps prevented any visibility on the conveyor. It became impossible to quickly detect a blockage, a jam, or the start of a fire.

- Complex infrastructure: the installation was located in a large sorting facility, equipped with numerous sorting lines. No lifting equipment (such as a MEWP/cherry picker) could access the area.

- Keeping waste within the process: in the event of wind, material falling, or belt jamming, waste could be projected out of the conveyor—creating health, environmental, and safety risks.

- Need for an adapted installation: removal of the tarps and installation of the new solution had to be carried out safely despite difficult access.

Solution proposed by OTEXIO

To meet all of these constraints, OTEXIO supplied and installed knotted braided polyethylene nets with a 50 mm mesh.

Total visibility on the conveyor

The 50 mm mesh makes it possible to visually follow the movement of waste. Operators can:

- Immediately identify a blockage or a jam,

- Continuously monitor proper belt operation,

- Instantly detect any potential incipient fire.

Waste containment within the process

The net plays an essential role in material retention:

- it prevents waste from being blown away by the wind,

- above all, it retains waste in the event of a fall or a jam—one of its key functions,

- it helps maintain a clean and safe environment around the conveyor.

Controlled fire behavior

The polyethylene used provides slow burning, limiting flame spread in the event of an incident. This characteristic fully meets the fire-safety requirements imposed by the DREAL.

Easier installation despite restricted access

The nets are lightweight and can be installed without lifting equipment, which was essential given the site configuration.

Expert intervention: tarp removal + net installation

One of the main challenges of the job was the impossibility of access for MEWPs or any other equipment due to the density of the sorting lines.

To ensure a safe and compliant installation, OTEXIO brought in a specialized team of professional rope access technicians, able to work in complex and confined environments.

Thanks to their expertise: the opaque tarps were removed safely, the nets were installed accurately and efficiently over the entire conveyor, and the work was completed quickly, safely, and without disrupting site operations.

This ability to deliver a turnkey solution—combining equipment + specialized installation—is one of OTEXIO’s strengths on this project.

Results & client feedback

The client is fully satisfied with the outcome:

- The installation is now compliant with the fire-safety requirements imposed by the DREAL.

- Operational visibility is significantly improved, enabling real-time monitoring of waste flow.

- Waste remains contained within the process, even in the event of a jam, fully securing the area.

- The site benefits from a notable reduction in risks, particularly fire-related risks.

- The tailored intervention, carried out by specialized rope access technicians, met the site’s constraints exactly.

Previous tarps

New nets

A question? A quote?

If you would like a quote or if you have any questions, we are here to help.

Tel.: +33 (0)4 78 05 21 27